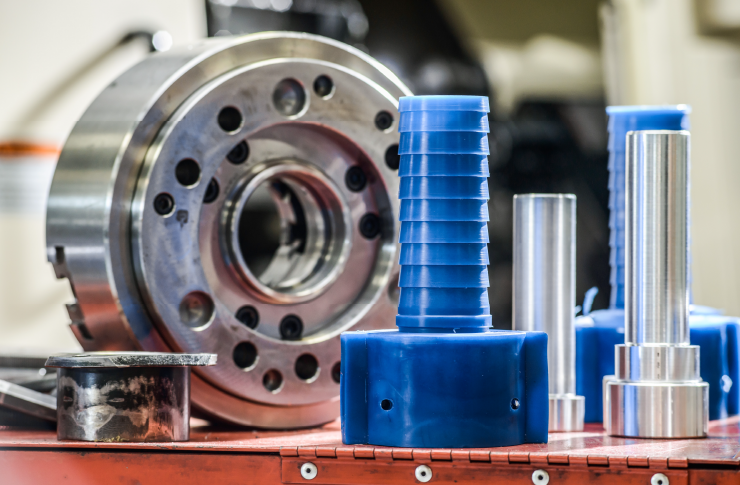

WHAT IS UHMW-PE AND IS IT BETTER?

UHMW-PE is formed in molds from a powder using a combination of high compression and high temperatures. Flexible and durable, UHMW-PE and the way we work with it have many benefits over metals and other plastics.

- Less waste

- Lighter weight

- Low friction

- Impact and temperature resistant

- Self-lubricating and sanitary

OUR PROCESS: HOW WE WORK

The Global Polymer team is accustomed to solving the problems customers bring us, problems they or other plastics manufacturers couldn’t solve. Bring us your hand sketch or computer drawing and we’ll take it from there to turn a complicated problem into a concrete product. We’ll create a 3D drawing, design a compression mold, build the mold, and use our innovative production process to deliver volume and consistency at a competitive price.

If you’re doing a good job, it gets noticed.

INDUSTRIES WE SERVE

Seeking parts that wear well in challenging environments, companies working in agriculture, transportation, oil & gas, and manufacturing have found we can meet their UHMW-PE needs. We’ve produced bearings, wear plates, skids, rollers, bumpers, sprockets and a host of other durable parts.