WE STEP UP WHERE OTHERS FEAR TO TREAD

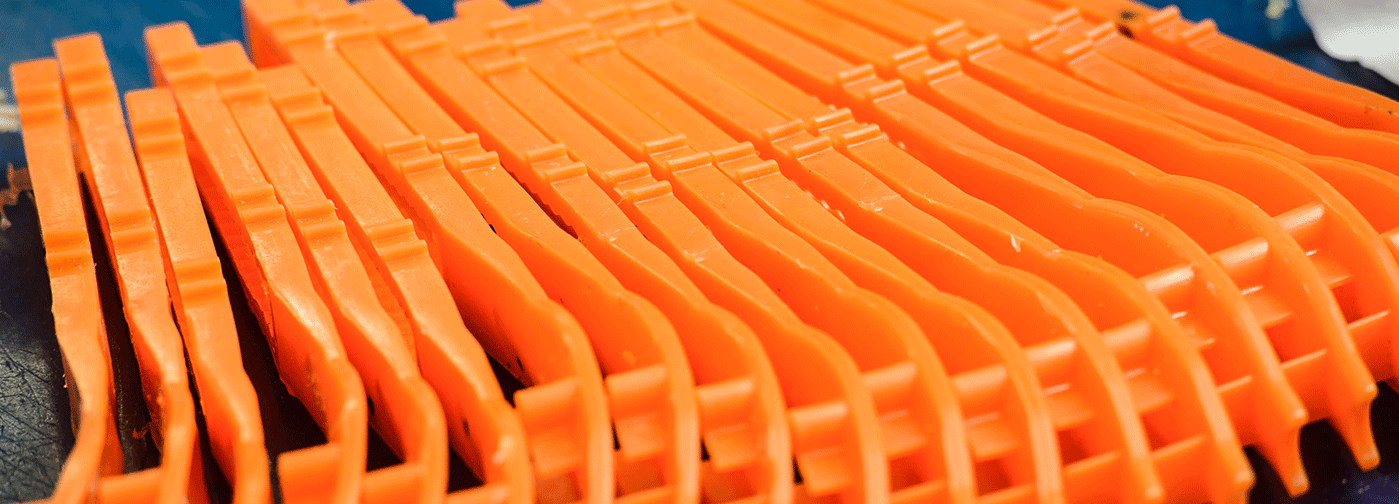

Two major drawbacks have prevented UHMW from much broader application. It’s difficult to mold into complex parts, and it lacks stiffness over longer spans. We took on those challenges. And mastered them. Our proprietary molding process produces the most complex shapes with repeatable precision. We’ve also learned to embed steel core to create parts that have all the advantages of UHMW, plus exceptional strength and durability. Or spring steel to create flexible parts with high shape memory.

INDUSTRIES WE SERVE

INDUSTRIAL

UHMW-PE is being used for hundreds of applications in mining, construction, chemical plants, waste water treatment plants, just to name a few. These industrial plants have the need for impact toughness, corrosion resistance, and biological inertness. UHMW-PE is used as scrapers, bushings, gears, conveyor rollers and more.

AGRICULTURAL

UHMW-PE will make your agriculture machinery last longer, run more efficiently, and will reduce operating and maintenance costs.

RECREATIONAL

UHMW-PE is used for a variety of parts for recreation vehicles such as snowmobile skis, bogey wheels, drive sprockets, idler arms and rollers.

FOOD AND DRUG

Tobacco, cosmetic and pharmaceutical packaging machines use UHMW-PE parts which operate clean without contamination, lubricants, rust or corrosion. UHMW-PE parts slide easily without staining or sticking. Drive parts outwear those made of stainless steel and cost less. Cleaning with steam or strong detergents cause no harm to UHMW-PE parts. With FDA clearance and USDA acceptance for food contact, UHMW-PE parts are safe and sanitary.

MARINE

Because UHMW-PE is non-marking, non-abrasive and virtually an unbreakable material, dock and boatlift manufacturers use UHMW-PE for bumpers, fenders, rub rails, etc.

TRANSPORTATION

Truck suspension manufacturers use UHMW-PE parts for wear plates, shims, bearings, etc. Railroad cars use UHMW-PE for wear plates, shims and coupler carriers.

Application Examples:

- Auger Bearings

- Cable Guides

- Conveyer Worm Screws

- Hanger Bearings

- Augers

- Cams

- Crowner Discharge

- Mixer Paddles

- Bearing Blocks

- Cam Followers

- Cutting Surfaces

- Picker Parts

- Bearing Seals

- Cam Guides

- Feed Screws

- Pulleys

- Bearing Shields

- Chain Covers

- Feeder Arm Tips

- Rack and Pinions

- Bearings

- Chain Guides

- Flat Chain Wear Plates

- Rotating Seals & Bearings

- Belt Guide Rollers

- Chain Wear Plates

- Flow Guides

- Shaker Table Surfaces

- Belt Idlers

- Chutes

- Gears & Sprockets

- Slides

- Blower Fins

- Conveyor Belt Wipers

- Guide Assemblies

- Sliding Bearings

- Bogey Wheels

- Conveyor Flights

- Guides Plates and Rails

- Star Wheels

- Bumper Blocks

- Conveyor Rollers

- Guide Rollers

- Telescope Rod Bearings

- Bushings

- Chain-Tensioning Blocks

- Glue Sealer Surfaces

- Snowmobile Skis

It’s a part that has worked out well for us and our customers. (UHMW) is lighter weight and much more corrosion resistant.