UHMW CHARACTERISTICS

UHMW-PE has a low coefficient of friction, decreasing the energy needed to operate machinery. The agriculture industry has found that using UHMW-PE as opposed to steel in scraper applications increased fuel economy, reduced noise levels and increased wear resistance. In material handling, the use of UHMW-PE sprockets and bearing surfaces have not only improved overall performance but have extended the life of conveying systems. In food handling systems UHMW-PE has eliminated the need for unwanted grease or oil lubricating methods, in fact, UHMW-PE is FDA and USDA approved for direct food contact.

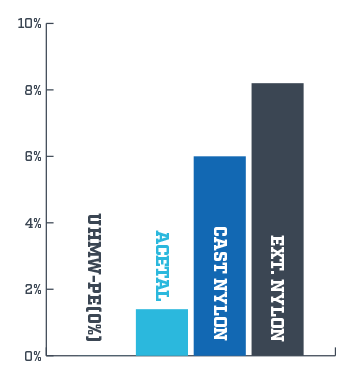

ALUMINUM OXIDE SLURRY ABRASION TEST

A 27″ (68mm) x 1″(25mm) x 0.25″ (6.3mm)

plaque 1750 rpm for 2 hours Controlled

temperature of 23°C

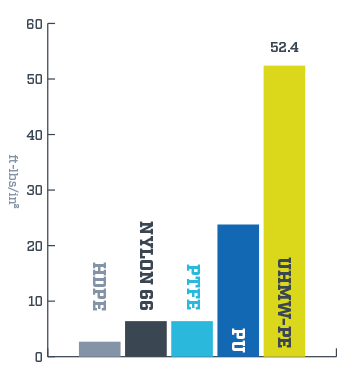

THE BEST ABRASION

RESISTANCE

Aluminum oxide slurry test

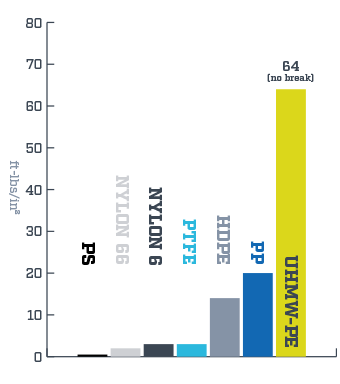

THE HIGHEST DOUBLE

NOTCHED IZOD IMPACT

Test method: ASTM D4020-96

Measured at 23°C

THE HIGHEST

NOTCHED IZOD IMPACT

Test method: ASTM D256-93A

Measured at 23°C

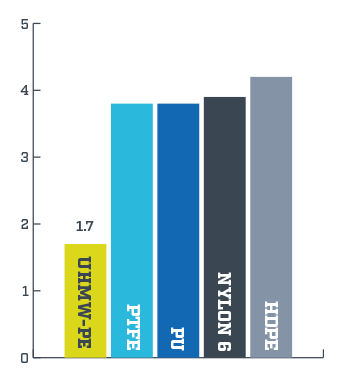

ASORBS THE LEAST

AMOUNT OF MOISTURE

% of absorption

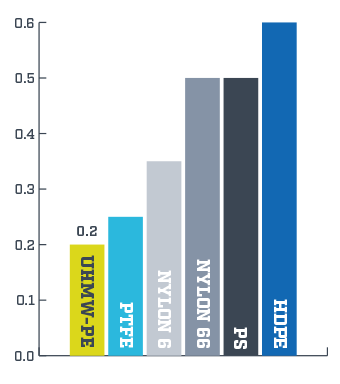

THE BEST STATIC

COEFFICIENT OF FRICTION

Against polished steel

Test method: ASTM 1894-95

Measured at 23°C